Manufacturing Design

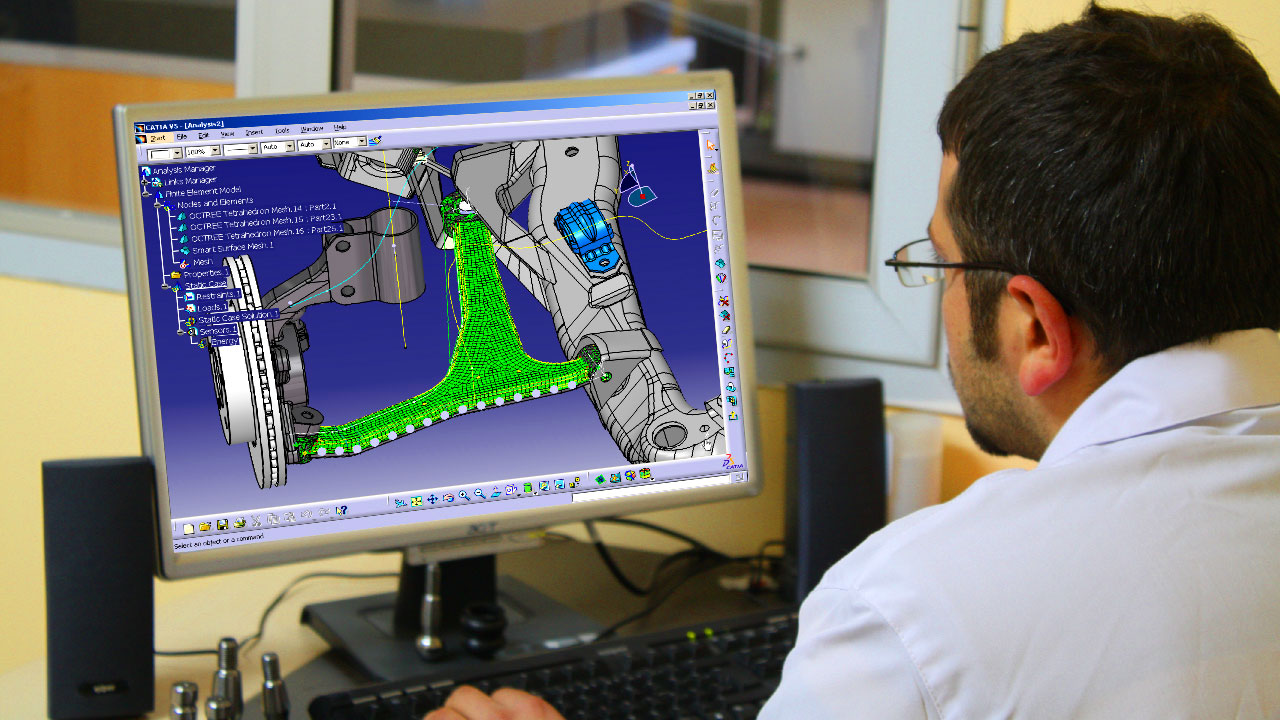

RIW makes testing of each process in quality, benchmarking, molding, raw materials, patents and original parts with ZW3D or AutoCAD for designing products. Product feasibility studies are being carried out in the process of commissioning new products in line with the requests from our customers.

In order to offer the equal or better quality to the market, RIW studies on OE parts which are the main tools in production design.

By applying its long years of experiences on designs and configuration processes, RIW offers the most economical, the safest and the highest quality solutions to its customers by designing the most productive products.

Being the solution partner in the every area is the main principle of RIW. By blending its experiences with the integration of computer aided design, engineering and manufacturing (CAD / CAM) methods, RIW targets continously development and improvement for the next item and process.